Fiber Comparison

Ribbond's success has led to the introductions of other fiber reinforcements. Although many manufacturers have tried to imitate Ribbond, none of them has proven themselves equal to Ribbond. Published independent evaluations and respected educators indicate a preference for Ribbond over the other fiber reinforcements. The most significant reason for their preference is Ribbond's unsurpassed manageability. Call us for a sample to see Ribbond's unique manageability for yourself.

Watch the videos

Important characteristics to consider when evaluating a fiber reinforcement

Fiber Configuration

Unidirectional fibers or woven reinforcements that spread apart when adapted are susceptible to slippage and crack propagation throughout the resin matrix when the prosthesis is stressed while in use.

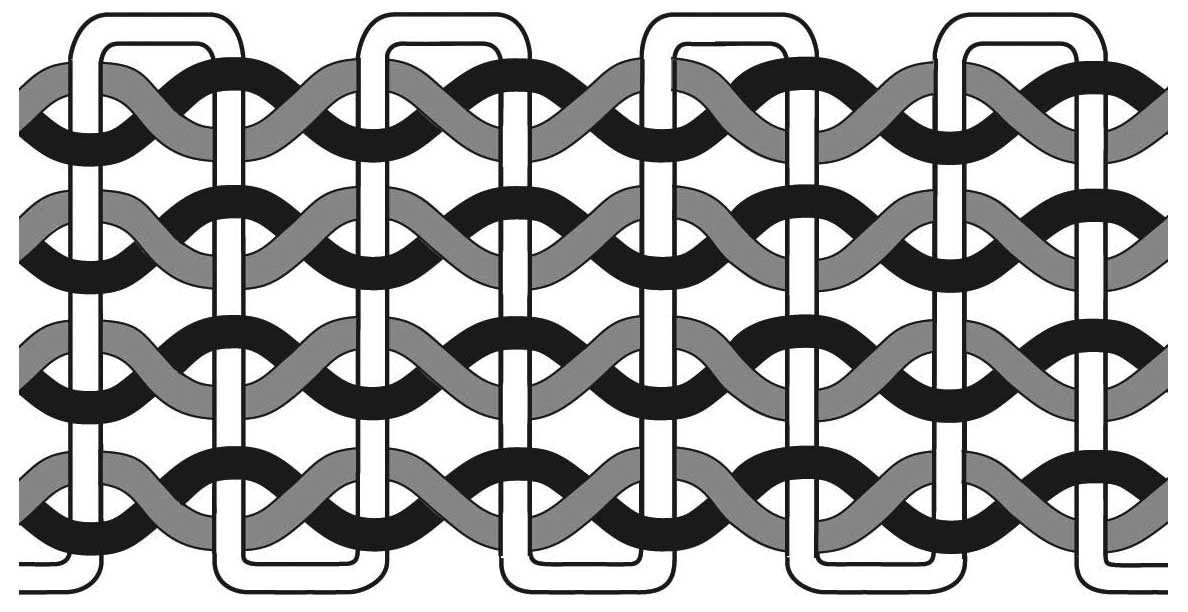

Ribbond's patented cross-link lock stitch leno weave provides unsurpassed manageability without compromising its multi-directional integrity and its ability to reinforce the composite.

This patented weave's lock stitch feature prevents slippage of the fibers within the resin so it will not unravel when cut or spread out when adapted.

Ribbond's Leno weave

Lack of Memory and Manageability

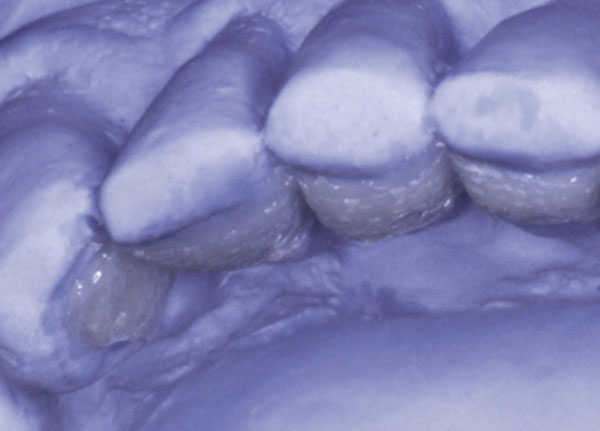

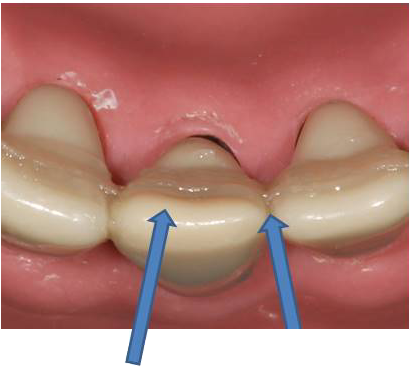

Perhaps as important as weave stability is a fiber reinforcement's lack of memory. Materials that rebound will not only result in excessive bulkiness, but will also compromise its laminated effect. Ribbond is virtually memory-free which insures close and accurate adaptation. In the case of a periodontal splint, placing the fibers closely against the tooth surface makes a laminate structure.

A fiber-reinforced composite is strong when the fiber is laminated closely to the teeth but prone to cohesive failure of the resin when the fiber is not closely adapted to the teeth. An example of this laminate phenomenon is the strength of a porcelain veneer when laminated closely to a tooth.

In the case of a bridges or other stress-bearing freestanding structures, fibers can be made into a laminate by placing them in multiple layers.

Easy to adapt - Virtually no memory

(photo not to scale)

Documented History of Success

Ribbond leads the field in published articles and studies. Ribbond has a proven record of success dating back to 1992. For the most up-to-date bibliography of articles and studies featuring Ribbond, please contact us. Many of these articles are also available upon request.

Biocompatibility

Unlike fiberglass, if at anytime the Ribbond is cut into with a rotary instrument, the resultant particles and exposed fibers will not be a biocompatibility risk to the patient.

Ribbond vs. glass fibers

The same fibers used to make Ribbond are used to make bullet proof vests and protective armor for military aircraft. While some manufacturers offer glass fiber reinforcements, glass fibers are not used for similar industrial applications for obvious reasons; glass fibers are brittle and are not fracture tough.

Competitor's braided weave

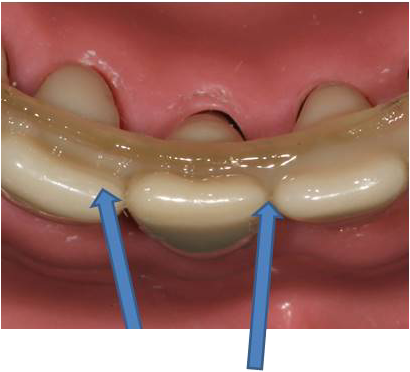

Loosely braided materials unravel and spread apart when adapted to the teeth. This creates a bulky and uncomfortable prostheses for your patients. Loosely braided materials also lack a mechanical interlocking of one fiber to the next, which comprises its fracture toughness.

Any first year student in structural engineering will tell you that it is easier to design a structure for stiffness using non-stiff materials than it is to design a structure for fracture toughness using non-fracture tough materials. Stiffness is achieved via design by the fibers being placed to make a laminate structure. Ribbond’s superior manageability allows for the most accurate placement of any fiber reinforcement. Accurate and close placement against the surfaces of the teeth minimizes the bond line and maximizes the laminate effect.

Ribbond's superior manageability allows for comfortable prostheses with thin bond lines.

Glass Fibers result in thick bond lines.

Ribbond’s superior manageability and superior fracture toughness provides the most clinically dependable fiber reinforcement on the market. Click to read more…

Indefinite Shelf Life

Ribbond has an indefinite shelf life and does not require refrigeration, maximizing cost effectiveness.